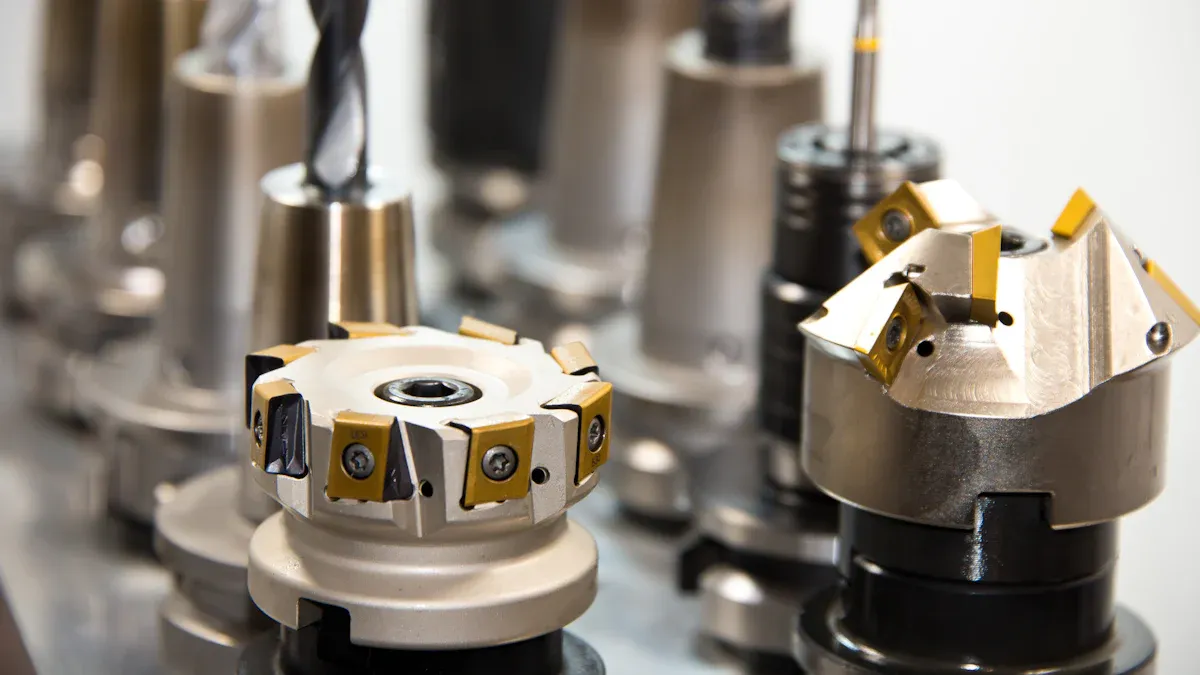

Selecting the appropriate Milling Cutters is crucial for optimizing machining efficiency, extending tool life, and achieving superior part quality. This guide provides essential factors for making informed decisions. It helps professionals choose the right milling cutters for their specific applications.

Key Takeaways

- Match your milling cutter to the material you are cutting. Different materials like aluminum or steel need specific cutter types for the best results.

- Choose the right Cutter for your job. Roughing needs cutters that remove a lot of material, while finishing needs cutters that make surfaces smooth.

- Use the shortest and widest cutter you can. This makes the tool stronger and helps it cut better without bending or breaking.

Understanding Material and Operation for Milling Cutters

Matching Milling Cutters to Material Properties

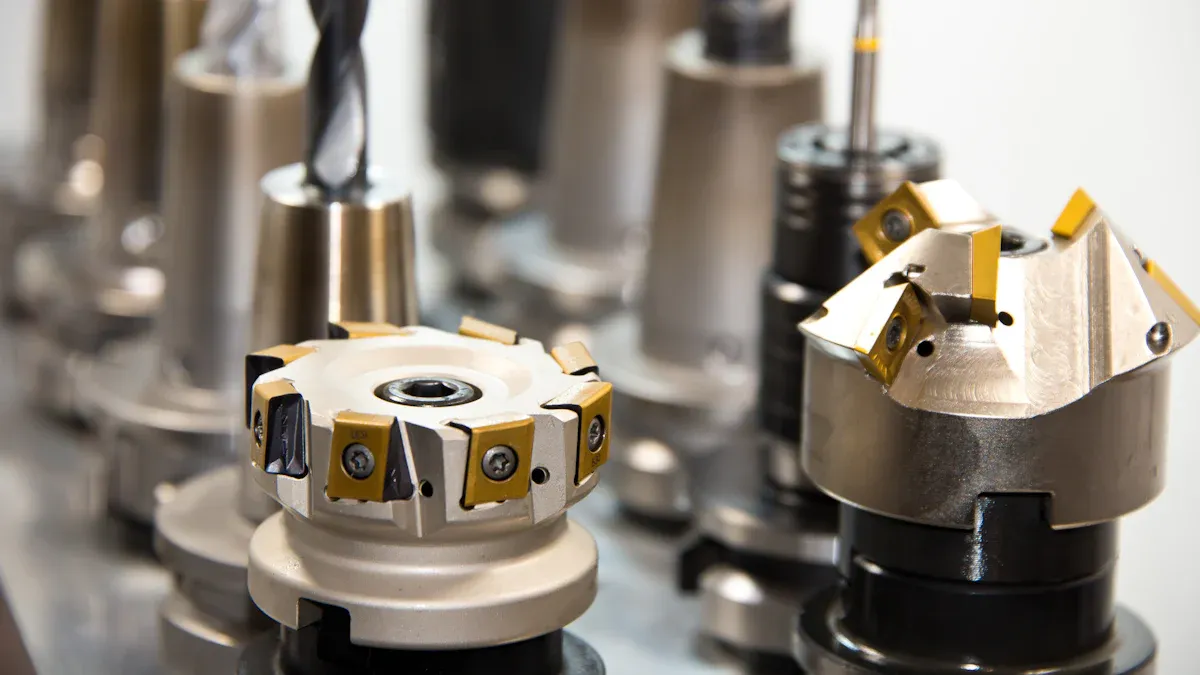

Selecting the right milling cutters involves a deep understanding of the workpiece material. The material's properties directly influence the optimal cutter choice. For instance, when machining aluminum alloys, specific milling cutters prove most effective. Spiral flute End Mills are recommended for their ability to remove chips efficiently, preventing accumulation that could impair the milling process. Shank cutters offer versatility; their flute count (1, 2, 3, or 4) depends on the aluminum alloy's hardness, with harder aluminum requiring more flutes to minimize wear. High-Speed Steel (HSS) end mills, made of high-speed steel, provide high hardness, wear resistance, and durability, available in various designs and cutting edge geometries. Indexable insert milling cutters, featuring a milling body with replaceable inserts, allow for precise and efficient milling as users can rotate or replace worn inserts. Solid carbide end mills, primarily made of tungsten carbide, are designed for high cutting speeds and feeds, offering long tool life due to their hardness and wear resistance, making them suitable for demanding milling work.

For stainless steel, optimal geometry requires sharp and positive designs, similar to aluminum. Endmills inherently possess a sharp and positive geometry, making them suitable for stainless steel. Forty-five-degree fast feed face mills are highly effective, especially when tool life is a primary concern, performing well on nickel and chrome-based materials. A noticeable trend involves using 5-6 flute 1/2" endmills or roughers for stainless steel applications. Cermet inserts, specifically NTK RPG and RNG types, show potential as optimal materials for inserts in stainless steel machining.

Material hardness and abrasiveness are critical factors in milling cutter material selection. The tool material must match or exceed the hardness and abrasiveness of the workpiece. Carbide, for example, is suitable for high-speed machining of hard materials, while High-Speed Steel (HSS) is ideal for general-purpose applications. Higher cutting speeds often necessitate harder materials like carbide or ceramics, which also offer longer tool life. The selection of cutting tool materials is influenced by the workpiece material, machining conditions, and required surface quality. Balancing hardness and toughness is crucial; for instance, a finer grain size in cemented carbide increases its hardness. Different materials offer varying levels of hardness and wear resistance: High-Speed Steel (HSS) maintains hardness at high temperatures, while carbides provide superior hardness, higher temperature resistance, and wear resistance. Ceramics and silicon nitride are suitable for high-temperature machining, further emphasizing the need to match the tool to the workpiece's properties.

Selecting Milling Cutters for Specific Operations

The type of machining operation significantly influences the choice of milling cutters. For roughing operations, which involve removing significant material during initial machining stages, specific designs are most effective. Roughing end mills are specifically designed for this purpose. They feature a coarse and rugged geometry, multiple flutes, a coarse tooth design, high helix angles, corner radii, and Weldon shanks, enabling high material removal rates. Square end mills are also suitable for roughing operations, in addition to finishing. They have flat, square-shaped tips with sharp corners, allowing for straightforward machining of flat surfaces, slots, and profiles. They can add precision to roughing operations and are considered general-purpose cutting tools.

For achieving fine surface finishes in finishing operations, several milling cutter types are ideal. Positive rake cutting geometries reduce cutting forces and deflection, leading to a finer surface finish by biting into material shear planes with less force. Sharper inserts, often ground inserts, contribute to better surface finishes due to their sharper edges, though they can be more expensive than pressed or molded ones. High helix and variable helix cutters inherently produce a better finish. Variable helix cutters further improve finish by disrupting chatter vibrations, preventing them from settling on a single frequency. Increasing the number of flutes or inserts is akin to increasing RPM for surface finish, especially beneficial for mills with limited spindle speeds; however, chip clearance must be considered. Forty-five-degree lead angle facemills often yield a superior finish compared to 90-degree facemills and allow for faster feed rates due to thinner chips. 'Wiper' inserts feature a flat ground that burnishes the workpiece after the leading edge cuts, significantly improving surface finish, though proper spindle tilt is crucial. Polycrystalline Diamond (PCD) flycutters are known for producing exceptionally smooth finishes on aluminum. Bullnose or corner radius end mills and round inserts (button cutters) provide a finer finish than flat endmills. While round inserts can be prone to chatter, their large radius delivers an excellent finish when stable.

Slotting operations significantly influence milling cutter flute geometry selection, particularly flute count. For precision slotting applications, such as creating woodruff key slots or gear teeth slots, considering both the cutter geometry and the flute count of the milling tool is crucial. Tools with more flutes generally have a larger core, increasing tool strength but reducing flute valley size, which can hinder chip evacuation in heavy material removal. Conversely, fewer flutes offer larger valleys for better chip evacuation, suitable for softer materials like aluminum where strength is less critical. For harder materials like steel, a larger core and more flutes provide necessary strength and productivity, despite smaller chip valleys. Modern machining has seen a shift towards higher flute counts (e.g., 3 flutes for non-ferrous, 5-7+ for ferrous) to balance productivity, tool life, and chip evacuation. The type of operation also matters: roughing often benefits from lower flute counts for chip evacuation, while finishing operations favor higher flute counts for better surface finish, as chip evacuation is less of a concern.

The Role of Cutter Material and Coatings

The choice of cutter material and the application of coatings play a pivotal role in optimizing milling performance and tool longevity. Carbide cutting tools allow for significantly higher spindle speeds, up to three times faster than HSS. Carbide can effectively cut materials too hard for HSS tooling, such as hardened shanks, and contributes to improved productivity through faster metal removal rates. Carbide inserts offer convenience as users can quickly change or rotate them in seconds, minimizing downtime.

Various coatings significantly extend tool life, especially in abrasive materials. Titanium Carbo Nitride adds hardness and decreases friction, beneficial for cutting adhesive materials like aluminum. Aluminum Titanium Nitride and Titanium Aluminum Nitride form an ultrathin layer of aluminum oxide, maintaining hardness at high speeds and temperatures, suitable for dry machining or working with cast iron and other abrasive metals. Chromium Nitride offers low friction, high hot hardness, and corrosion resistance, preventing chemical bonds between the cutting material and the tool. Aluminum Chromium Nitride provides additional wear resistance under mechanical stress due to aluminum, with a very high oxidation temperature, transferring heat away from the tool in dry cutting applications. Tungsten Carbide is highly resistant to temperature and friction, also aiding in chip evacuation. Triton, a high-density diamond-like carbon, is extra resistant to corrosion, abrasion, and adhesion, often used for machining nonferrous metals like aluminum and abrasive plastics in minimal-lubricant settings. For example, BALINIT Hard Carbon (PVD coating) on carbide end mill tooling for HDD aluminum alloy baseplates produced 95% more parts with 55% lower production costs than untreated tooling. A Hard Carbon-coated counter sink tool for CFRP and thermoplastics produced 180% more parts than an uncoated tool. PACVD-based diamond coated cutting tools for Duralcan composite (ceramic particle-reinforced aluminum) drilled 20 times more holes compared to 'diamond-like' carbon coatings.

| Feature/Coating Type | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Hardness | Generally improves wear resistance and tool life | Allows lower cutting forces |

| Temperature Resistance | Good for high-speed machining | Withstands higher cutting temperatures better |

| Best for Workpiece Materials | Aluminum, non-ferrous alloys, hardened steels, superalloys, non-ferrous and abrasive materials (e.g., aluminum alloys, graphite, composites) | Titanium, nickel, cobalt alloys, cast iron, steel |

| Common Coatings | TiN, TiAlN, AlTiN, CrN, DLC | TiN (some grades), TiCN, Al₂O₃ |

| Key Advantage for Milling | Uniformity, hardness, high precision non-ferrous work | Heat resistance, adhesion, suitable for tough materials |

| Specific Application Examples | High-speed machining of aluminum, general-purpose for drills/mills/taps, high-speed/dry machining, machining hardened steels/superalloys, machining non-ferrous/abrasive materials | Steel machining (TiCN), high-speed cutting of cast iron and steel (Al₂O₃) |

Ceramic milling cutters offer specific material properties for high-temperature applications. They exhibit resistance to high-temperature deformation, making them suitable for high-speed milling. They also show resistance to abrasive wear, contributing to their effectiveness in high-speed milling. Strengthening additives like SiC and TiC enhance their abrasion resistance, strength, and fracture toughness. High hardness is a key feature of ceramic-composite materials. These cutters also possess high-temperature mechanical stability, a property particularly utilized in specialty cutter designs for high-speed milling.

Key Characteristics of Milling Cutters: Geometry and Size

Flute Count and Helix Angle for Optimal Performance

Flute count significantly impacts chip evacuation and surface finish. End mills with more flutes generally provide a smoother finish because they take smaller cuts. However, an increased number of flutes reduces the space within the flute valleys. This can limit chip evacuation, especially with larger chips. Therefore, higher flute counts are optimal for finishing applications where chip evacuation is less critical. Roughing operations, conversely, benefit from lower flute counts to ensure sufficient space for chip clearance.

Increasing the flute count generally leads to a finer surface finish. This happens because the tool produces smaller chips. However, this can impede chip evacuation due to reduced space in the flute valleys. Fewer flutes allow for better chip evacuation but may result in a rougher surface finish, particularly in softer materials. The optimal flute count depends on the specific machining task, the desired surface finish, and the material being machined.

Higher flute counts are recommended for finishing operations. They provide smoother finishes and reduced cutting forces. While more flutes increase tool strength and suit tougher materials, they also reduce the flute valleys. This can hinder chip evacuation. For roughing operations, a lower flute count is preferred to ensure adequate chip evacuation. The relationship is clear: more flutes yield smoother finishes, while fewer flutes enable faster material removal.

For rough machining, a smaller number of flutes ensures larger flute valleys for efficient chip evacuation. In contrast, end mills with a high number of flutes suit finishing operations. They remove less material and chip evacuation does not significantly affect them, leading to smoother surfaces. This highlights a trade-off: more flutes result in a smoother surface, while fewer flutes allow for a faster material removal rate.

The choice of flute count involves a constant balancing act. This balance considers tool strength, chip evacuation space, and achievable feed rate. Increasing the flute count generally makes the tool stronger and capable of producing a better finish. However, it reduces the space available for chip evacuation. Conversely, decreasing the flute count enhances chip removal capability. This comes at the cost of tool rigidity and potential surface quality. A higher flute count results in a larger, stronger core diameter. A lower flute count necessitates deeper flute valleys, leading to a smaller, weaker core. The flute valley's primary role is chip evacuation. Large, deep valleys (low flute count) are crucial for materials producing large chips, like aluminum. Smaller valleys (high flute count) can lead to chip recutting and tool failure if used incorrectly. More flutes also allow for higher feed rates and finer surface finishes. The cutting load distributes among more edges, resulting in smaller, finer bites.

| Flute Count | Core Diameter (Strength) | Flute Valley (Chip Room) | Potential Feed Rate | Typical Surface Finish |

|---|---|---|---|---|

| Low (2-3) | Smaller / Weaker | Large / Excellent | Slower | Coarser |

| High (4+) | Larger / Stronger | Small / Poor | Faster | Finer |

| Material Group | Primary Challenge | Recommended Flute Count | Why? |

|---|---|---|---|

| Soft Materials (Aluminum, Plastics, Brass) | Large, Gummy Chips | 2 or 3 Flutes | To maximize chip evacuation and prevent clogging or chip welding. |

| General Purpose Steels (Carbon, Alloy, Cast Iron) | Tool Strength and Stability | 4 Flutes | For increased tool strength, smoother cut, better surface finish, and longer tool life. |

| Hardened Steels, Titanium, Superalloys | Extreme Cutting Pressure, Heat | 5+ Flutes | For maximum rigidity and distributing the cutting load to prevent chatter or snapping. |

The helix angle of a milling cutter also plays a critical role. It influences cutting forces, chip evacuation, and surface finish. For milling in steel, some experts suggest a helix angle of approximately 3-5 degrees. However, the optimal angle can depend on factors such as the size of the hole and the face geometry of the end mill.

A high helix angle significantly improves cutting stability, especially in difficult-to-machine materials.

- A larger helix angle reduces peak cutting forces. It distributes the load more evenly across the cutting edge.

- Larger helix angles improve surface quality and reduce cutting forces in Ti6Al4V alloy. This leads to a 34.71% reduction in average cutting force and a 276.32% reduction in surface roughness.

- A 45° helix angle achieves optimal surface roughness for C45 steel. This indicates a positive effect of increased helix angle on surface quality under high-speed cutting.

- Increasing the helix angle to 50° for AlZn5.5MgCu alloy reduces cutting forces and improves chip evacuation. This enhances cutting efficiency.

- Experiments on MgO–WF show that increasing the helix angle from 20° to 50° reduces cutting forces and improves surface quality. It decreases roughness and tool wear.

- A larger helix angle (55%) reduces cutting forces and improves surface integrity when milling 2024-T351 aluminum alloy. This is crucial for thin-walled, low-stiffness parts.

End Styles and Their Applications

Milling cutter end styles dictate their primary applications and the types of features they can create.

Square end mills are versatile tools. They feature flat, square-shaped tips with sharp corners. These tools allow for straightforward machining of flat surfaces, slots, and profiles. Their primary applications include:

- Face milling: They remove material from the surface of a workpiece to create flat surfaces. Carbide square end mills, especially center cutting ones, are effective for this.

- Side milling: This involves using a cutting tool with teeth on the side to create slots or grooves. Carbide square end mills (high-speed steel and center cutting) suit removing material from the side of the workpiece.

- Plunge cutting

- Slotting

- Pocketing

- General milling applications

- Creating square bottomed slots

- Creating square bottomed pockets

- Cutting flat surfaces

- Profiling

Ball nose milling cutters feature a spherical cutting end. This design makes them ideal for machining contoured surfaces. Manufacturers often use them for:

- 3D contouring and surface machining

- Mold making (injection molds, die-casting dies, stamping tools)

- Finishing operations for automotive, consumer electronics, and industrial parts

- Creating perfect radii in internal corners and cavity bottoms

- Prototyping and artistic applications involving organic shapes

- Machining 3-dimensional contour shapes

- The mold and die industry

- Manufacturing of turbine blades

- Fulfilling general part radius requirements

Corner radius milling cutters incorporate a rounded edge instead of a sharp corner. This design allows for smoother machining processes and improves tool life. This design reduces stress concentrations at corners, enhancing the overall strength of the machined part. The rounded corners help dissipate cutting forces more evenly. This extends tool life, especially when machining tough materials like stainless steel. The tool can maintain its edge longer than traditional flat-edge cutters. This leads to cost savings and increased productivity by reducing the frequency of tool replacements.

| Feature | Corner Radius End Mills | Square End Mills |

|---|---|---|

| Tool Life | Consistently outlast by 25-40% | Vulnerable to chipping and premature wear |

| Cutting Force Distribution | Distribute cutting forces more evenly | Sharp corner acts as a stress concentration point |

| Heat Buildup | Reduced heat buildup and wear | Higher heat buildup |

| Part Strength | Eliminates sharp transitions that can cause stress concentrations | Can cause stress concentrations |

| Benefits | Fewer tool changes, more consistent part quality, lower tooling costs, enhanced tool strength, better surface finish, longer tool life, higher feed rates | Prone to chipping and premature wear, especially with harder materials |

Importance of Milling Cutter Diameter and Length

The physical dimensions of a milling cutter, specifically its diameter and length, significantly influence machining stability, accuracy, and efficiency.

The diameter of a milling cutter directly affects its rigidity and the amount of material it can remove per pass. Generally, using the largest possible diameter for a given application enhances rigidity and performance. A larger diameter tool can withstand greater cutting forces and reduce deflection.

The length of a milling cutter critically impacts tool deflection during machining.

- Tool Overhang: The longer the tool extends beyond the holder, the greater the risk of deflection. This happens due to reduced rigidity. Minimizing overhang by clamping the tool securely is crucial for optimal cutting conditions.

- Flute Length: Shorter flute lengths enhance rigidity and reduce deflection. Deflection minimizes when only the tool tip engages in cutting.

- Core Diameter (for long flute tools): For long flute tools, the core diameter, rather than the cutting diameter, is the critical factor for determining deflection. Cutting edges do not provide structural support. A larger core diameter provides greater rigidity.

- When the ratio between a tool's length and diameter (l/ϕ) is significant, tool deflection becomes the primary cause of machining errors.

- To maximize rigidity and minimize deflection, manufacturers recommend using the shortest possible tool.

Guidelines exist for selecting the shortest possible length for milling cutters for a given depth of cut.

- To prevent damage to the cutting tool, minimize the distance between the end mill tip and the toolholder.

- Choose the shortest possible end mill length to maximize rigidity.

- Use longer end mills for machining seamless walls or for finishing operations in slots or pockets.

- Select long-reach end mills when continuous, full-depth cuts are not necessary, but increased rigidity is still required.

For High Efficiency Milling (HEM), manufacturers recommend utilizing as much of the cutter's flute length as possible. This approach allows for deeper cuts, potentially completing a pocket in a single pass rather than multiple layers. Spreading wear over a longer flute length extends cutter life and allows for more aggressive machining parameters.

Specific considerations apply to different cut types:

- For slot cuts, the maximum depth should generally not exceed the diameter of the end mill. For example, a 1/4" end mill can cut 1/4" deep per pass.

- For profiling cuts (axial depth of cut), the maximum engagement of the end mill with the workpiece should be about 1.5 times the end mill's diameter. For instance, a 1/4" end mill can engage up to 3/16" of its length. This guideline primarily addresses end mill deflection, though carbide tools may tolerate more.

Machine and Setup Considerations for Milling CuttersMachine Rigidity and Spindle Power

Machine rigidity and spindle power are crucial for selecting milling cutters. These capabilities directly influence optimal depth of cut and feed rate. Rigid machines handle larger depths of cut and higher forces without stressing components. Machines with greater power and stability manage increased forces and vibrations effectively. Machine power and rigidity also directly influence the feed rate. More robust machines enable faster material removal. Weaker machines struggle with higher speeds and feeds, leading to poor results. Adjusting parameters based on the CNC machine's capability ensures stable conditions.

Machining vibration causes oscillations between the cutting tool and workpiece. This leads to poor surface finishes, reduced tool life, and slower speeds. Vibration degrades surface quality, creating undesirable wavy patterns. In high-precision applications, vibration results in high scrap rates. Vibration impacts tool life and spindles, especially in hardened materials. Chatter on machined surfaces degrades surface quality and dimensional accuracy. Spindle speed is a primary factor influencing tool vibrations. Vibration amplitude increases with tool wear and higher cutting speed/feed rate. Reducing spindle speed significantly decreases cutting vibrations.

Optimizing Cutting Speed and Feed Rates

Optimizing cutting speed and feed rates is crucial for efficient machining and extended tool life. Toolmakers provide recommended cutting speeds for various workpiece materials. For example, 100 surface feet per minute (sfm) means the tool's outer surface moves at 100 feet per minute. Cutting speed is the tangential velocity at the cutting interface. You can calculate spindle speed (rpm) using: spindle speed (rpm) = cutting speed (sfm) * 3.82 / tool diameter.

Optimizing the feed rate

Selecting the appropriate milling cutters is crucial for optimizing machining efficiency, extending tool life, and achieving superior part quality. This guide provides essential factors for making informed decisions. It helps professionals choose the right milling cutters for their specific applications.

Key Takeaways

- Match your milling cutter to the material you are cutting. Different materials like aluminum or steel need specific cutter types for the best results.

- Choose the right cutter for your job. Roughing needs cutters that remove a lot of material, while finishing needs cutters that make surfaces smooth.

- Use the shortest and widest cutter you can. This makes the tool stronger and helps it cut better without bending or breaking.

Understanding Material and Operation for Milling Cutters

Matching Milling Cutters to Material Properties

Selecting the right milling cutters involves a deep understanding of the workpiece material. The material's properties directly influence the optimal cutter choice. For instance, when machining aluminum alloys, specific milling cutters prove most effective. Spiral flute end mills are recommended for their ability to remove chips efficiently, preventing accumulation that could impair the milling process. Shank cutters offer versatility; their flute count (1, 2, 3, or 4) depends on the aluminum alloy's hardness, with harder aluminum requiring more flutes to minimize wear. High-Speed Steel (HSS) end mills, made of high-speed steel, provide high hardness, wear resistance, and durability, available in various designs and cutting edge geometries. Indexable insert milling cutters, featuring a milling body with replaceable inserts, allow for precise and efficient milling as users can rotate or replace worn inserts. Solid carbide end mills, primarily made of tungsten carbide, are designed for high cutting speeds and feeds, offering long tool life due to their hardness and wear resistance, making them suitable for demanding milling work.

For stainless steel, optimal geometry requires sharp and positive designs, similar to aluminum. Endmills inherently possess a sharp and positive geometry, making them suitable for stainless steel. Forty-five-degree fast feed face mills are highly effective, especially when tool life is a primary concern, performing well on nickel and chrome-based materials. A noticeable trend involves using 5-6 flute 1/2" endmills or roughers for stainless steel applications. Cermet inserts, specifically NTK RPG and RNG types, show potential as optimal materials for inserts in stainless steel machining.

Material hardness and abrasiveness are critical factors in milling cutter material selection. The tool material must match or exceed the hardness and abrasiveness of the workpiece. Carbide, for example, is suitable for high-speed machining of hard materials, while High-Speed Steel (HSS) is ideal for general-purpose applications. Higher cutting speeds often necessitate harder materials like carbide or ceramics, which also offer longer tool life. The selection of cutting tool materials is influenced by the workpiece material, machining conditions, and required surface quality. Balancing hardness and toughness is crucial; for instance, a finer grain size in cemented carbide increases its hardness. Different materials offer varying levels of hardness and wear resistance: High-Speed Steel (HSS) maintains hardness at high temperatures, while carbides provide superior hardness, higher temperature resistance, and wear resistance. Ceramics and silicon nitride are suitable for high-temperature machining, further emphasizing the need to match the tool to the workpiece's properties.

Selecting Milling Cutters for Specific Operations

The type of machining operation significantly influences the choice of milling cutters. For roughing operations, which involve removing significant material during initial machining stages, specific designs are most effective. Roughing end mills are specifically designed for this purpose. They feature a coarse and rugged geometry, multiple flutes, a coarse tooth design, high helix angles, corner radii, and Weldon shanks, enabling high material removal rates. Square end mills are also suitable for roughing operations, in addition to finishing. They have flat, square-shaped tips with sharp corners, allowing for straightforward machining of flat surfaces, slots, and profiles. They can add precision to roughing operations and are considered general-purpose cutting tools.

For achieving fine surface finishes in finishing operations, several milling cutter types are ideal. Positive rake cutting geometries reduce cutting forces and deflection, leading to a finer surface finish by biting into material shear planes with less force. Sharper inserts, often ground inserts, contribute to better surface finishes due to their sharper edges, though they can be more expensive than pressed or molded ones. High helix and variable helix cutters inherently produce a better finish. Variable helix cutters further improve finish by disrupting chatter vibrations, preventing them from settling on a single frequency. Increasing the number of flutes or inserts is akin to increasing RPM for surface finish, especially beneficial for mills with limited spindle speeds; however, chip clearance must be considered. Forty-five-degree lead angle facemills often yield a superior finish compared to 90-degree facemills and allow for faster feed rates due to thinner chips. 'Wiper' inserts feature a flat ground that burnishes the workpiece after the leading edge cuts, significantly improving surface finish, though proper spindle tilt is crucial. Polycrystalline Diamond (PCD) flycutters are known for producing exceptionally smooth finishes on aluminum. Bullnose or corner radius end mills and round inserts (button cutters) provide a finer finish than flat endmills. While round inserts can be prone to chatter, their large radius delivers an excellent finish when stable.

Slotting operations significantly influence milling cutter flute geometry selection, particularly flute count. For precision slotting applications, such as creating woodruff key slots or gear teeth slots, considering both the cutter geometry and the flute count of the milling tool is crucial. Tools with more flutes generally have a larger core, increasing tool strength but reducing flute valley size, which can hinder chip evacuation in heavy material removal. Conversely, fewer flutes offer larger valleys for better chip evacuation, suitable for softer materials like aluminum where strength is less critical. For harder materials like steel, a larger core and more flutes provide necessary strength and productivity, despite smaller chip valleys. Modern machining has seen a shift towards higher flute counts (e.g., 3 flutes for non-ferrous, 5-7+ for ferrous) to balance productivity, tool life, and chip evacuation. The type of operation also matters: roughing often benefits from lower flute counts for chip evacuation, while finishing operations favor higher flute counts for better surface finish, as chip evacuation is less of a concern.

The Role of Cutter Material and Coatings

The choice of cutter material and the application of coatings play a pivotal role in optimizing milling performance and tool longevity. Carbide cutting tools allow for significantly higher spindle speeds, up to three times faster than HSS. Carbide can effectively cut materials too hard for HSS tooling, such as hardened shanks, and contributes to improved productivity through faster metal removal rates. Carbide inserts offer convenience as users can quickly change or rotate them in seconds, minimizing downtime.

Various coatings significantly extend tool life, especially in abrasive materials. Titanium Carbo Nitride adds hardness and decreases friction, beneficial for cutting adhesive materials like aluminum. Aluminum Titanium Nitride and Titanium Aluminum Nitride form an ultrathin layer of aluminum oxide, maintaining hardness at high speeds and temperatures, suitable for dry machining or working with cast iron and other abrasive metals. Chromium Nitride offers low friction, high hot hardness, and corrosion resistance, preventing chemical bonds between the cutting material and the tool. Aluminum Chromium Nitride provides additional wear resistance under mechanical stress due to aluminum, with a very high oxidation temperature, transferring heat away from the tool in dry cutting applications. Tungsten Carbide is highly resistant to temperature and friction, also aiding in chip evacuation. Triton, a high-density diamond-like carbon, is extra resistant to corrosion, abrasion, and adhesion, often used for machining nonferrous metals like aluminum and abrasive plastics in minimal-lubricant settings. For example, BALINIT Hard Carbon (PVD coating) on carbide end mill tooling for HDD aluminum alloy baseplates produced 95% more parts with 55% lower production costs than untreated tooling. A Hard Carbon-coated counter sink tool for CFRP and thermoplastics produced 180% more parts than an uncoated tool. PACVD-based diamond coated cutting tools for Duralcan composite (ceramic particle-reinforced aluminum) drilled 20 times more holes compared to 'diamond-like' carbon coatings.

| Feature/Coating Type | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Hardness | Generally improves wear resistance and tool life | Allows lower cutting forces |

| Temperature Resistance | Good for high-speed machining | Withstands higher cutting temperatures better |

| Best for Workpiece Materials | Aluminum, non-ferrous alloys, hardened steels, superalloys, non-ferrous and abrasive materials (e.g., aluminum alloys, graphite, composites) | Titanium, nickel, cobalt alloys, cast iron, steel |

| Common Coatings | TiN, TiAlN, AlTiN, CrN, DLC | TiN (some grades), TiCN, Al₂O₃ |

| Key Advantage for Milling | Uniformity, hardness, high precision non-ferrous work | Heat resistance, adhesion, suitable for tough materials |

| Specific Application Examples | High-speed machining of aluminum, general-purpose for drills/mills/taps, high-speed/dry machining, machining hardened steels/superalloys, machining non-ferrous/abrasive materials | Steel machining (TiCN), high-speed cutting of cast iron and steel (Al₂O₃) |

Ceramic milling cutters offer specific material properties for high-temperature applications. They exhibit resistance to high-temperature deformation, making them suitable for high-speed milling. They also show resistance to abrasive wear, contributing to their effectiveness in high-speed milling. Strengthening additives like SiC and TiC enhance their abrasion resistance, strength, and fracture toughness. High hardness is a key feature of ceramic-composite materials. These cutters also possess high-temperature mechanical stability, a property particularly utilized in specialty cutter designs for high-speed milling.

Key Characteristics of Milling Cutters: Geometry and Size

Flute Count and Helix Angle for Optimal Performance

Flute count significantly impacts chip evacuation and surface finish. End mills with more flutes generally provide a smoother finish because they take smaller cuts. However, an increased number of flutes reduces the space within the flute valleys. This can limit chip evacuation, especially with larger chips. Therefore, higher flute counts are optimal for finishing applications where chip evacuation is less critical. Roughing operations, conversely, benefit from lower flute counts to ensure sufficient space for chip clearance.

Increasing the flute count generally leads to a finer surface finish. This happens because the tool produces smaller chips. However, this can impede chip evacuation due to reduced space in the flute valleys. Fewer flutes allow for better chip evacuation but may result in a rougher surface finish, particularly in softer materials. The optimal flute count depends on the specific machining task, the desired surface finish, and the material being machined.

Higher flute counts are recommended for finishing operations. They provide smoother finishes and reduced cutting forces. While more flutes increase tool strength and suit tougher materials, they also reduce the flute valleys. This can hinder chip evacuation. For roughing operations, a lower flute count is preferred to ensure adequate chip evacuation. The relationship is clear: more flutes yield smoother finishes, while fewer flutes enable faster material removal.

For rough machining, a smaller number of flutes ensures larger flute valleys for efficient chip evacuation. In contrast, end mills with a high number of flutes suit finishing operations. They remove less material and chip evacuation does not significantly affect them, leading to smoother surfaces. This highlights a trade-off: more flutes result in a smoother surface, while fewer flutes allow for a faster material removal rate.

The choice of flute count involves a constant balancing act. This balance considers tool strength, chip evacuation space, and achievable feed rate. Increasing the flute count generally makes the tool stronger and capable of producing a better finish. However, it reduces the space available for chip evacuation. Conversely, decreasing the flute count enhances chip removal capability. This comes at the cost of tool rigidity and potential surface quality. A higher flute count results in a larger, stronger core diameter. A lower flute count necessitates deeper flute valleys, leading to a smaller, weaker core. The flute valley's primary role is chip evacuation. Large, deep valleys (low flute count) are crucial for materials producing large chips, like aluminum. Smaller valleys (high flute count) can lead to chip recutting and tool failure if used incorrectly. More flutes also allow for higher feed rates and finer surface finishes. The cutting load distributes among more edges, resulting in smaller, finer bites.

| Flute Count | Core Diameter (Strength) | Flute Valley (Chip Room) | Potential Feed Rate | Typical Surface Finish |

|---|---|---|---|---|

| Low (2-3) | Smaller / Weaker | Large / Excellent | Slower | Coarser |

| High (4+) | Larger / Stronger | Small / Poor | Faster | Finer |

| Material Group | Primary Challenge | Recommended Flute Count | Why? |

|---|---|---|---|

| Soft Materials (Aluminum, Plastics, Brass) | Large, Gummy Chips | 2 or 3 Flutes | To maximize chip evacuation and prevent clogging or chip welding. |

| General Purpose Steels (Carbon, Alloy, Cast Iron) | Tool Strength and Stability | 4 Flutes | For increased tool strength, smoother cut, better surface finish, and longer tool life. |

| Hardened Steels, Titanium, Superalloys | Extreme Cutting Pressure, Heat | 5+ Flutes | For maximum rigidity and distributing the cutting load to prevent chatter or snapping. |

The helix angle of a milling cutter also plays a critical role. It influences cutting forces, chip evacuation, and surface finish. For milling in steel, some experts suggest a helix angle of approximately 3-5 degrees. However, the optimal angle can depend on factors such as the size of the hole and the face geometry of the end mill.

A high helix angle significantly improves cutting stability, especially in difficult-to-machine materials.

- A larger helix angle reduces peak cutting forces. It distributes the load more evenly across the cutting edge.

- Larger helix angles improve surface quality and reduce cutting forces in Ti6Al4V alloy. This leads to a 34.71% reduction in average cutting force and a 276.32% reduction in surface roughness.

- A 45° helix angle achieves optimal surface roughness for C45 steel. This indicates a positive effect of increased helix angle on surface quality under high-speed cutting.

- Increasing the helix angle to 50° for AlZn5.5MgCu alloy reduces cutting forces and improves chip evacuation. This enhances cutting efficiency.

- Experiments on MgO–WF show that increasing the helix angle from 20° to 50° reduces cutting forces and improves surface quality. It decreases roughness and tool wear.

- A larger helix angle (55%) reduces cutting forces and improves surface integrity when milling 2024-T351 aluminum alloy. This is crucial for thin-walled, low-stiffness parts.

End Styles and Their Applications

Milling cutter end styles dictate their primary applications and the types of features they can create.

Square end mills are versatile tools. They feature flat, square-shaped tips with sharp corners. These tools allow for straightforward machining of flat surfaces, slots, and profiles. Their primary applications include:

- Face milling: They remove material from the surface of a workpiece to create flat surfaces. Carbide square end mills, especially center cutting ones, are effective for this.

- Side milling: This involves using a cutting tool with teeth on the side to create slots or grooves. Carbide square end mills (high-speed steel and center cutting) suit removing material from the side of the workpiece.

- Plunge cutting

- Slotting

- Pocketing

- General milling applications

- Creating square bottomed slots

- Creating square bottomed pockets

- Cutting flat surfaces

- Profiling

Ball nose milling cutters feature a spherical cutting end. This design makes them ideal for machining contoured surfaces. Manufacturers often use them for:

- 3D contouring and surface machining

- Mold making (injection molds, die-casting dies, stamping tools)

- Finishing operations for automotive, consumer electronics, and industrial parts

- Creating perfect radii in internal corners and cavity bottoms

- Prototyping and artistic applications involving organic shapes

- Machining 3-dimensional contour shapes

- The mold and die industry

- Manufacturing of turbine blades

- Fulfilling general part radius requirements

Corner radius milling cutters incorporate a rounded edge instead of a sharp corner. This design allows for smoother machining processes and improves tool life. This design reduces stress concentrations at corners, enhancing the overall strength of the machined part. The rounded corners help dissipate cutting forces more evenly. This extends tool life, especially when machining tough materials like stainless steel. The tool can maintain its edge longer than traditional flat-edge cutters. This leads to cost savings and increased productivity by reducing the frequency of tool replacements.

| Feature | Corner Radius End Mills | Square End Mills |

|---|---|---|

| Tool Life | Consistently outlast by 25-40% | Vulnerable to chipping and premature wear |

| Cutting Force Distribution | Distribute cutting forces more evenly | Sharp corner acts as a stress concentration point |

| Heat Buildup | Reduced heat buildup and wear | Higher heat buildup |

| Part Strength | Eliminates sharp transitions that can cause stress concentrations | Can cause stress concentrations |

| Benefits | Fewer tool changes, more consistent part quality, lower tooling costs, enhanced tool strength, better surface finish, longer tool life, higher feed rates | Prone to chipping and premature wear, especially with harder materials |

Importance of Milling Cutter Diameter and Length

The physical dimensions of a milling cutter, specifically its diameter and length, significantly influence machining stability, accuracy, and efficiency.

The diameter of a milling cutter directly affects its rigidity and the amount of material it can remove per pass. Generally, using the largest possible diameter for a given application enhances rigidity and performance. A larger diameter tool can withstand greater cutting forces and reduce deflection.

The length of a milling cutter critically impacts tool deflection during machining.

- Tool Overhang: The longer the tool extends beyond the holder, the greater the risk of deflection. This happens due to reduced rigidity. Minimizing overhang by clamping the tool securely is crucial for optimal cutting conditions.

- Flute Length: Shorter flute lengths enhance rigidity and reduce deflection. Deflection minimizes when only the tool tip engages in cutting.

- Core Diameter (for long flute tools): For long flute tools, the core diameter, rather than the cutting diameter, is the critical factor for determining deflection. Cutting edges do not provide structural support. A larger core diameter provides greater rigidity.

- When the ratio between a tool's length and diameter (l/ϕ) is significant, tool deflection becomes the primary cause of machining errors.

- To maximize rigidity and minimize deflection, manufacturers recommend using the shortest possible tool.

Guidelines exist for selecting the shortest possible length for milling cutters for a given depth of cut.

- To prevent damage to the cutting tool, minimize the distance between the end mill tip and the toolholder.

- Choose the shortest possible end mill length to maximize rigidity.

- Use longer end mills for machining seamless walls or for finishing operations in slots or pockets.

- Select long-reach end mills when continuous, full-depth cuts are not necessary, but increased rigidity is still required.

For High Efficiency Milling (HEM), manufacturers recommend utilizing as much of the cutter's flute length as possible. This approach allows for deeper cuts, potentially completing a pocket in a single pass rather than multiple layers. Spreading wear over a longer flute length extends cutter life and allows for more aggressive machining parameters.

Specific considerations apply to different cut types:

- For slot cuts, the maximum depth should generally not exceed the diameter of the end mill. For example, a 1/4" end mill can cut 1/4" deep per pass.

- For profiling cuts (axial depth of cut), the maximum engagement of the end mill with the workpiece should be about 1.5 times the end mill's diameter. For instance, a 1/4" end mill can engage up to 3/16" of its length. This guideline primarily addresses end mill deflection, though carbide tools may tolerate more.

Machine and Setup Considerations for Milling Cutters

Machine Rigidity and Spindle Power

Machine rigidity and spindle power are crucial for selecting milling cutters. These capabilities directly influence optimal depth of cut and feed rate. Rigid machines handle larger depths of cut and higher forces without stressing components. Machines with greater power and stability manage increased forces and vibrations effectively. Machine power and rigidity also directly influence the feed rate. More robust machines enable faster material removal. Weaker machines struggle with higher speeds and feeds, leading to poor results. Adjusting parameters based on the CNC machine's capability ensures stable conditions.

Machining vibration causes oscillations between the cutting tool and workpiece. This leads to poor surface finishes, reduced tool life, and slower speeds. Vibration degrades surface quality, creating undesirable wavy patterns. In high-precision applications, vibration results in high scrap rates. Vibration impacts tool life and spindles, especially in hardened materials. Chatter on machined surfaces degrades surface quality and dimensional accuracy. Spindle speed is a primary factor influencing tool vibrations. Vibration amplitude increases with tool wear and higher cutting speed/feed rate. Reducing spindle speed significantly decreases cutting vibrations.

Optimizing Cutting Speed and Feed Rates

Optimizing cutting speed and feed rates is crucial for efficient machining and extended tool life. Toolmakers provide recommended cutting speeds for various workpiece materials. For example, 100 surface feet per minute (sfm) means the tool's outer surface moves at 100 feet per minute. Cutting speed is the tangential velocity at the cutting interface. You can calculate spindle speed (rpm) using: spindle speed (rpm) = cutting speed (sfm) * 3.82 / tool diameter.

Optimizing the feed rate prevents tool wear and improves surface finish. An excessively high feed rate causes the tool to bounce or skip, resulting in a rough surface. A very low feed rate leads to prolonged grinding, increasing tool wear. Determine the ideal feed rate for your milling system to reduce surface roughness and extend tool life. Start with conservative feed rates and gradually increase them while monitoring tool behavior. Use manufacturer-recommended speeds and feeds as a starting point. Adjusting feed rates helps avoid machine natural frequencies, reducing chatter and promoting smoother operations.

Using the correct coolant significantly impacts cutting speed and efficiency. Coolants reduce heat, improve chip removal, and extend tool life. Improper application causes wear or distortion. Match the coolant type and flow rate to the material and operation. This maximizes cutting speeds without damaging the tool or workpiece. General recommendations for speeds and feeds typically assume coolant use. If dry cutting, reduce speeds to prevent tool damage. Some coatings, like AlTiN/TiAlN, are designed for dry use in steels. Heat enhances their durability. Coolant can cause thermal shock in these coatings, breaking them down more quickly.

Choosing the right milling cutter involves systematically evaluating material, operation, cutter geometry, coatings, and machine capabilities. Prioritize using the largest diameter and shortest tool possible for enhanced rigidity and performance. Always consult manufacturer recommendations. Conduct test cuts to validate the selection.

FAQWhat is the most critical factor when selecting a milling cutter?

Matching the cutter's material and geometry to the workpiece material is the most critical factor. This ensures optimal performance, efficiency, and tool life.

How does the flute count influence milling operations?

More flutes generally produce a smoother surface finish but reduce chip evacuation space. Fewer flutes improve chip removal, which is better for roughing operations.

When should machinists use a ball nose end mill?

Machinists use ball nose end mills for machining contoured surfaces and 3D shapes. They are ideal for mold making, finishing operations, and creating radii.

tool wear and improves surface finish. An excessively high feed rate causes the tool to bounce or skip, resulting in a rough surface. A very low feed rate leads to prolonged grinding, increasing tool wear. Determine the ideal feed rate for your milling system to reduce surface roughness and extend tool life. Start with conservative feed rates and gradually increase them while monitoring tool behavior. Use manufacturer-recommended speeds and feeds as a starting point. Adjusting feed rates helps avoid machine natural frequencies, reducing chatter and promoting smoother operations.

Using the correct coolant significantly impacts cutting speed and efficiency. Coolants reduce heat, improve chip removal, and extend tool life. Improper application causes wear or distortion. Match the coolant type and flow rate to the material and operation. This maximizes cutting speeds without damaging the tool or workpiece. General recommendations for speeds and feeds typically assume coolant use. If dry cutting, reduce speeds to prevent tool damage. Some coatings, like AlTiN/TiAlN, are designed for dry use in steels. Heat enhances their durability. Coolant can cause thermal shock in these coatings, breaking them down more quickly.

Choosing the right milling cutter involves systematically evaluating material, operation, cutter geometry, coatings, and machine capabilities. Prioritize using the largest diameter and shortest tool possible for enhanced rigidity and performance. Always consult manufacturer recommendations. Conduct test cuts to validate the selection.

FAQ

What is the most critical factor when selecting a milling cutter?

Matching the cutter's material and geometry to the workpiece material is the most critical factor. This ensures optimal performance, efficiency, and tool life.

How does the flute count influence milling operations?

More flutes generally produce a smoother surface finish but reduce chip evacuation space. Fewer flutes improve chip removal, which is better for roughing operations.

When should machinists use a ball nose end mill?

Machinists use ball nose end mills for machining contoured surfaces and 3D shapes. They are ideal for mold making, finishing operations, and creating radii.

Media Contact

Company Name: Ningbo Derek Tools Co., Ltd.

Email: Send Email

Country: China

Website: https://www.derekmall.com/