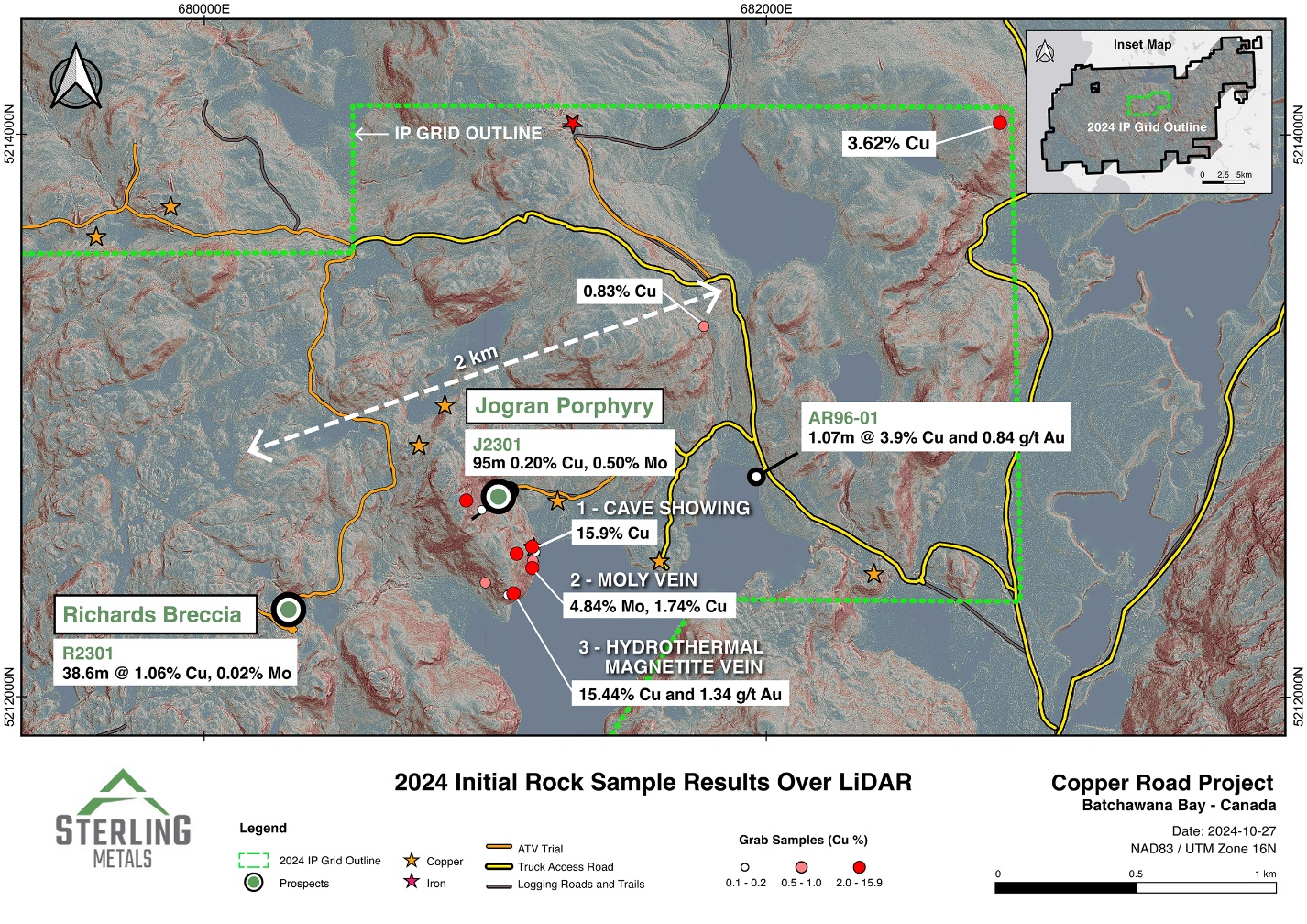

TORONTO, ON / ACCESSWIRE / October 29, 2024 / Sterling Metals Corp. (TSXV:SAG)(OTCQB:SAGGF) ("Sterling" or the "Company") is pleased to provide an exploration update on its inaugural Phase 1 campaign at the Copper Road Project ("Copper Road" or the "Project"). The campaign has successfully defined an initial 5 x 5km high priority area. Located 80km north of Sault Ste. Marie, Ontario, Canada, Copper Road is a 25,000ha high-potential brownfield exploration project focused on discovering a large rift-related porphyry copper-molybdenum-silver-gold deposit formed in association with the prolific Midcontinent Rift. The Project benefits from its strategic proximity to substantial infrastructure, excellent project access and extensive historical database.

Highlights

-

Discovery of high-grade copper and molybdenum sulphides, some with significant gold and silver contents, in multiple surface grab sample outcrops within the high-priority exploration area.

Values ranging up to 15.90% Cu and 4.84% Mo, with an average copper value of 1.96% Cu across 31 samples (Table 1).

Hydrothermal magnetite-sulphide veins grading up to 15.4% Cu, 54 g/t Ag and 1.34 g/t Au in the highest-grade sample.

-

The emergence of a ~2km long footprint of significant porphyry mineralization within the high priority area.

Previous drilling and surface outcrops have revealed a Cu-Mo rich mineral system containing chalcopyrite, bornite, pyrite and molybdenum with at least three distinct phases of mineralization.

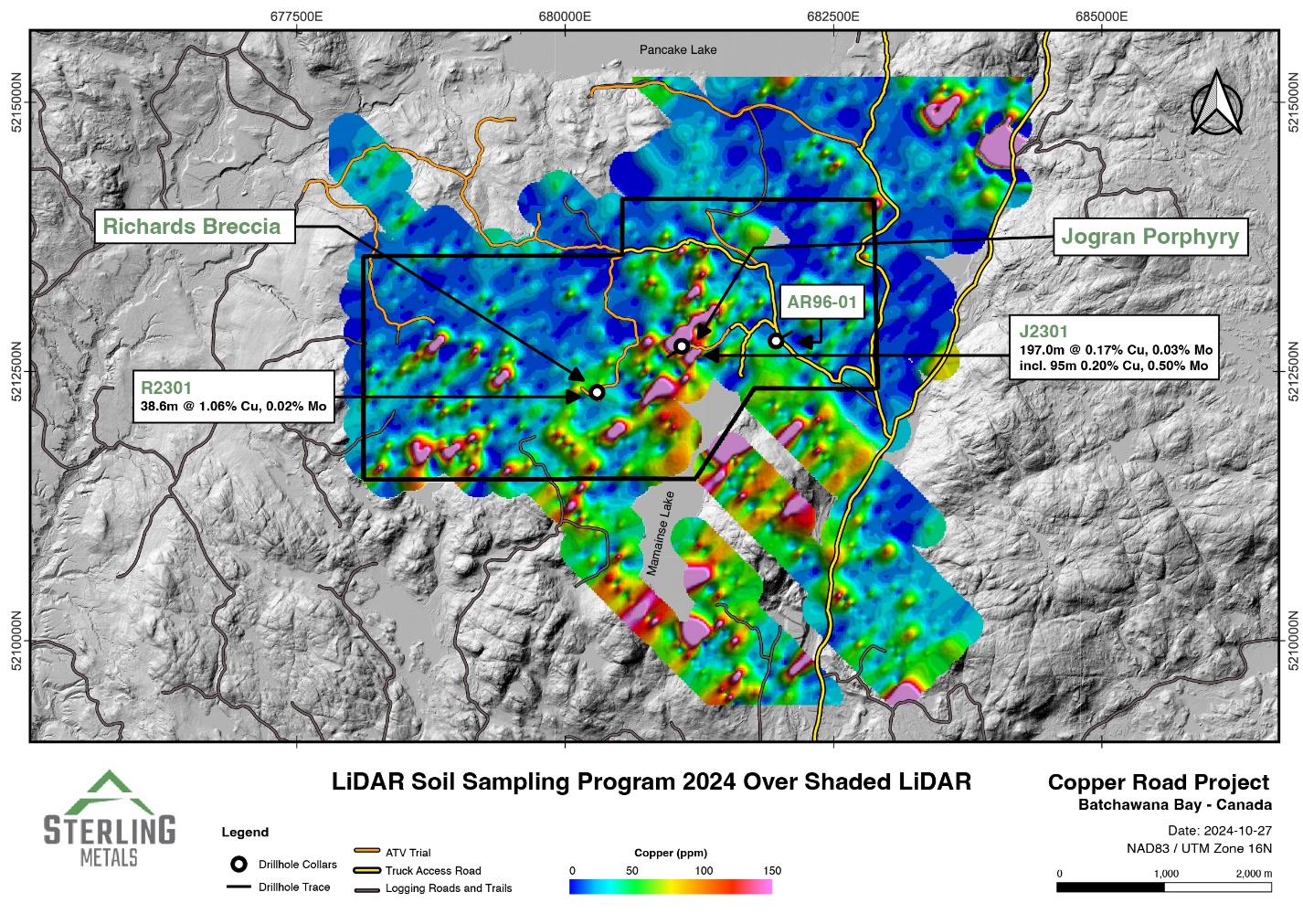

Porphyry style mineralization has now been traced from the Richards Breccia to the Jogran Porphyry, and further, from the newly identified outcrop to historical drill hole AR96-01 (Figure 1).

-

Completion of the 2024 soil sampling program further confirm consistent, strong copper-molybdenum anomalies (Figure 5).

Sampling covered a 23km2 area on a 50 by 200m grid, with a total of 1,822 samples collected demonstrating clear trends and several new areas of interest.

-

A 5km x 3km 3D IP survey is underway to guide drill targeting

The survey will build on insights from the summer field program and historical data to enhance definition of priority targets.

The analysis will focus specifically on zones just beyond Cu-Mo-Au-Ag mineralization incepted by the few historical holes that only tested to 200m vertical depth across the 2km footprint.

Jeremy Niemi, SVP Exploration and Evaluation, commented, "Our team is focused on discovering large-scale copper and molybdenum mineralization, and our recent work brings us another step closer in that goal. Completing our comprehensive soil sampling program has uncovered compelling copper and molybdenum trends across the central part of the Project. This systematic approach, combined with extensive fieldwork, has revealed several high-grade outcrops with multiple occurrences of copper, molybdenum and in some cases gold. Impressively, these outcrops are located hundreds of meters from previous drilling, highlighting the Project's large, mineralized footprint. The variety of mineralization styles we are seeing is also very encouraging and indicative of a copper-molybdenum rich porphyry type system. Our current IP survey is specifically designed to locate large porphyries and represents a key step forward in our target definition before we begin drilling."

Grab Samples

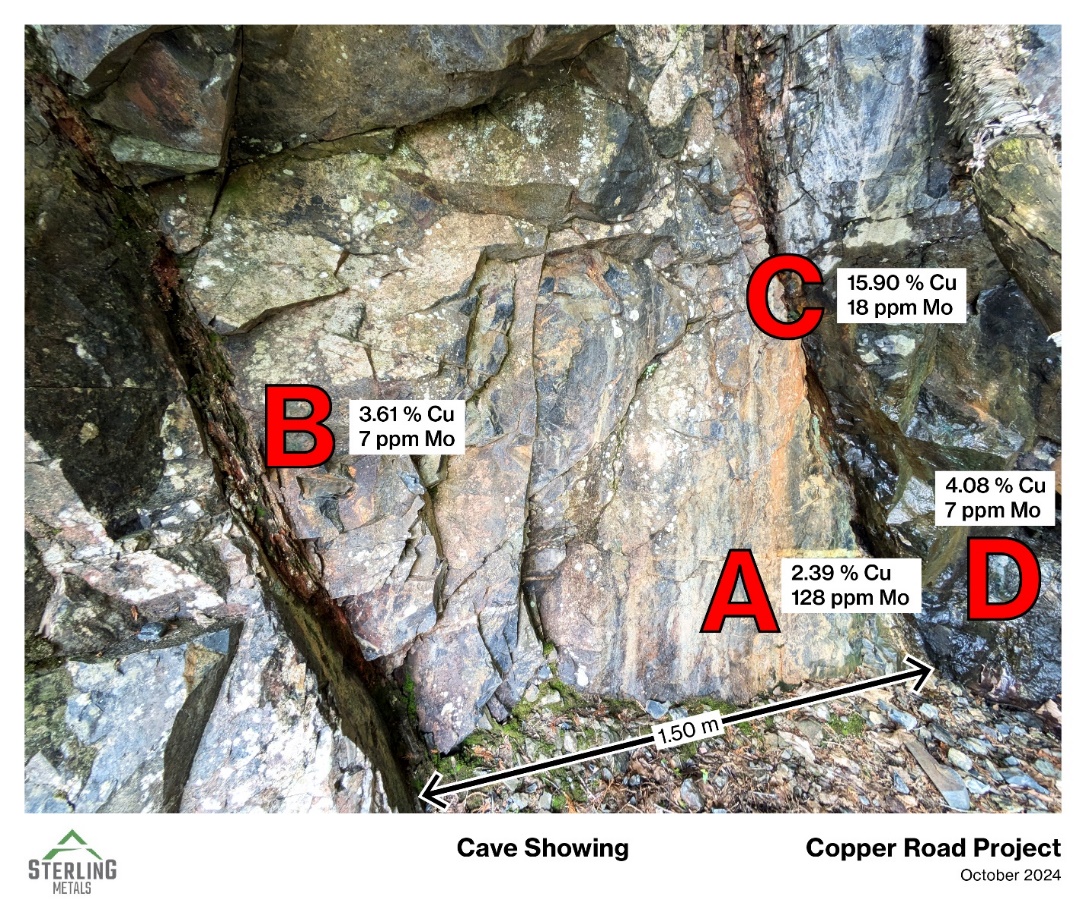

Copper and molybdenum sulphide mineralization was identified in outcrops in a number of locations across the property and within the limits of the current IP survey grid. Systematic sampling of the mineralization, typically present as porphyry style veining but also breccias, was carried out by the Sterling Metals exploration team. In some cases, with larger exposure at outcrops, multiple samples were collected from the same outcrop.

A total of 31 samples are reported in Table 1 and locations displayed on Figure 2. Copper values ranged up to 15.90% with the average value of all the samples being 1.96% Cu. The specific showings were highlighted due to their high-grades and importance to target advancement.

The Cave Showing is located 240m south of the known Jogran Porphyry, a well mineralized porphyry prospect that has seen only shallow drilling to date. Copper and molybdenum rich veining at Jogran is associated with strong magnetite-bearing potassic alteration of the host rocks. At the Cave Showing, which is over 5m wide, clusters of porphyry style veins hosting copper and molybdenum sulphides occur in multiple orientations. Steeply dipping copper sulphide rich veins grading between 2.39% and 15.9% Cu have been sampled in four locations spanning 1.5m of the overall showing (Figure 2). Within the same outcrop, flat lying veins generally with higher molybdenum values were observed in multiple locations. Sample A focused on the flat lying veins and retuned a value of 2.39% Cu and 0.013% (128ppm) Mo. Pervasive swarms of veins, both steep and flat lying, as well as pockets of disseminated sulphide mineralization characterize the outcrop, which has yet to be drill tested. Of particular significance is the observation that there are at least 3 separate but related episodes of veining which is key to forming high-grade porphyry style mineralization. Additionally, one of the copper-rich veins is rich in magnetite which may indicate a connection to a significant copper-magnetite rich potassic core which underlies the area between Jogran and the Cave Showing.

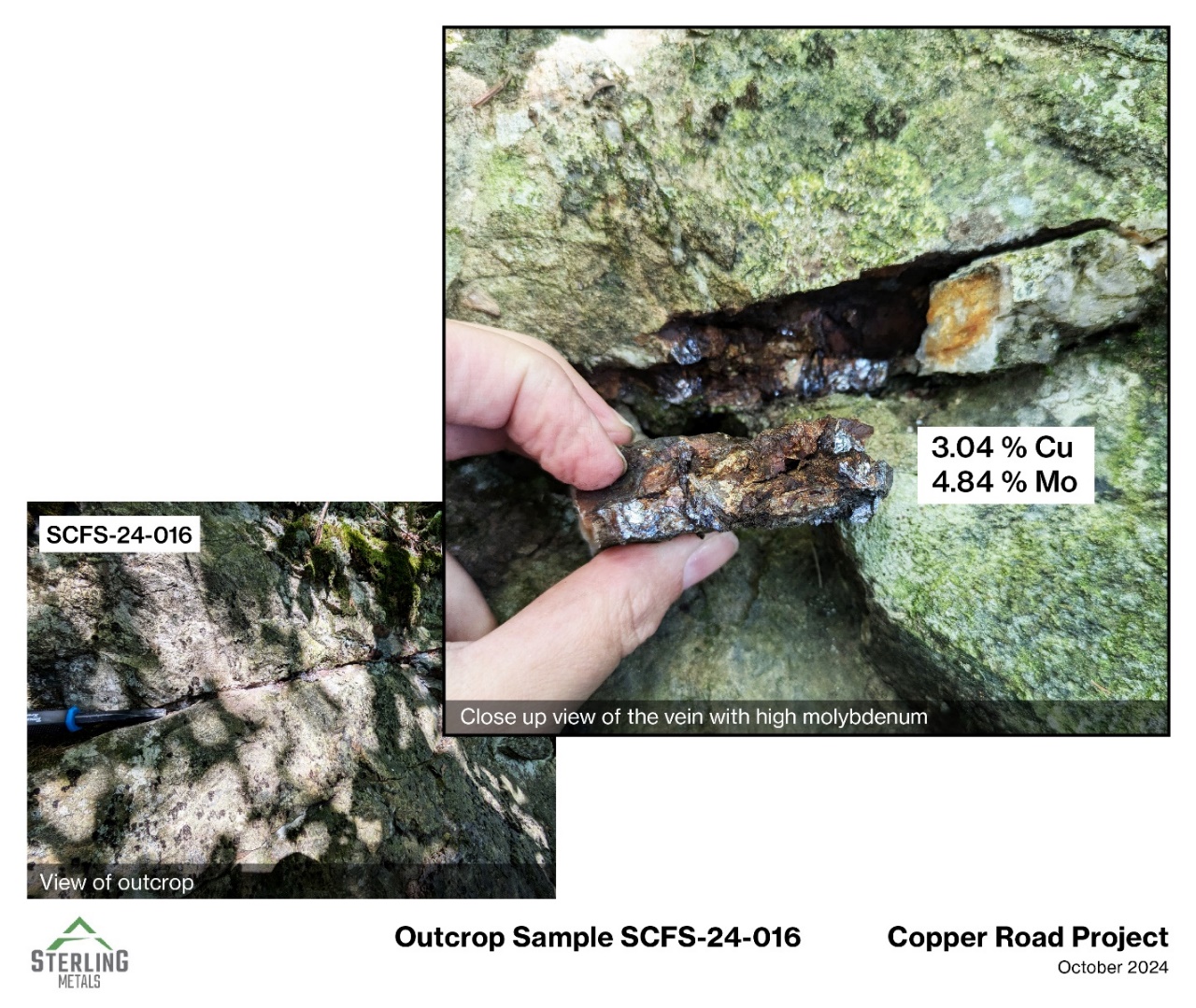

The Moly Vein is located an additional 50m beyond and south of the Cave Showing, 290m from the Jogran Porphyry. The flat lying vein, similar in orientation to the higher grading molybdenum veins at the Cave Showing, displayed very high-grade sulphide mineralization (Figure 3). The single sample collected at this location returned values of 1.74% Cu, 4.84% Mo and 3.04 g/t rhenium. Generally, a correlation between higher molybdenum values and higher rhenium values has been observed in historical samples at the property. Rhenium is an important potential revenue by-product metal that along with enrichment in molybdenum is common to rift-related porphyry copper deposits.

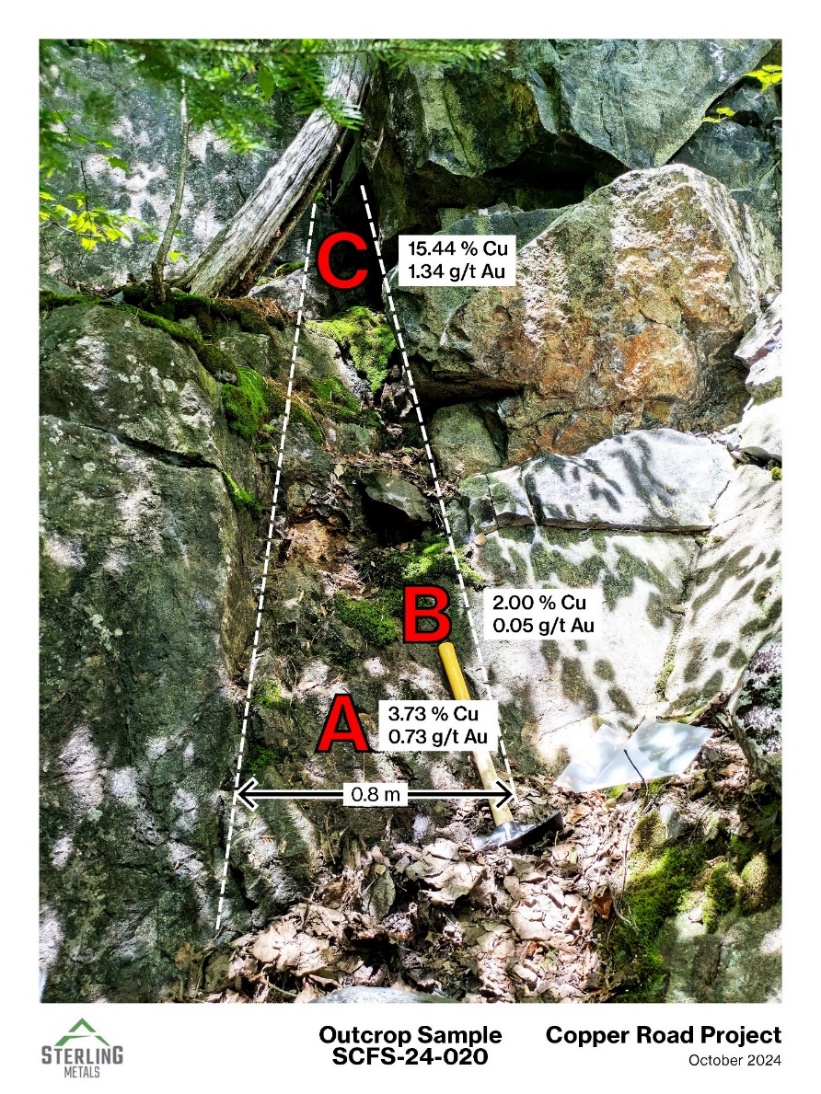

Located 100m south-west of the Moly Vein, a hydrothermal quartz-magnetite-sulphide vein was discovered hosting high-grade copper and gold mineralization. This 0.8m wide steeply dipping vein, which strikes to the north, was sampled in three locations (Figure 4). Copper values ranged from 2.00% to 15.44% and gold ranged between 0.05 g/t and 1.34 g/t. The vein, which consists of nearly massive magnetite, hosts abundant copper sulphides and is interpreted to be formed during the hot prograde stage of porphyry mineralization that characteristically also forms copper-rich magnetite-bearing potassic cores such as present in the Jogran Porphyry drill core.

Importantly, similar copper-rich quartz-magnetite-sulphide vein mineralization was intersected in historical hole AR96-01, as reported in a press release on June 26, 2024. The intersection in AR96-01 is over 1km to the north-east of the Hydrothermal Magnetite Vein, and interestingly the hole also ended in porphyry mineralization with drill logs commenting on visual chalcopyrite, bornite, pyrite and molybdenum. The Hydrothermal Magnetite Vein is yet to be drill tested. The copper-rich quartz-magnetite-sulphide veins that crop out over several square km of this prospective area are hosted within strongly altered mafic volcanics, including epidote-bearing propylitic alteration, suggesting that a large copper-rich potassic core may underlie this area at moderate depth and which has not been tested for by previous drilling campaigns.

IP Survey

Currently, an extensive 3D Induced Polarization survey is being conducted by Dias Geophysical Ltd. in the central area of the property, covering 15 square kilometres and both the 2024 soil sampling grid as well as the results reported herein from surface sampling are contained in the IP survey area (Figure 1). The goal of the survey is to identify new chargeability anomalies, which may indicate the presence of sulphide mineralization. Physical property measurements on copper mineralized historical drill core on the property confirmed that the mineralization was highly chargeable. The results of the survey are anticipated to lead to specific drill targets for future drilling campaigns.

Mathew Wilson, CEO and Director, commented, "Through our extensive work and the Project's rich history, we now recognize that Copper Road was formed in response to a major geological event, making it a uniquely situated rift-related porphyry copper system at the eastern edge of the Midcontinent Rift in Ontario. With copper-rich mineralization widespread across this multi-kilometer Project and leveraging extensive records from past mine production to both the northeast and southwest, we are excited to have narrowed in on the central part of the Project that we believe offers the best potential for a significant near-term discovery.

The goal of this IP survey is to identify potential zones of overlapping, multiple phases of high-grade copper sulfides, that may lead to uncovering a rich, and ideally extensive porphyry copper deposit. Priority drill targets will be defined by the alignment of IP anomalies with magnetics and resistivity anomalies where geological mapping and prior drilling results suggest the right conditions exist for significant concentrations of copper-rich sulphides. This is the final step prior to our inaugural drill program, and we look forward to updating the market when the inversions have been completed."

Table 1. Surface sampling results from 2024 field program.

Area |

Sample ID |

Easting (m) |

Northing (m) |

Cu (%) |

Mo ppm |

Mo % |

Re (g/t) |

Ag (g/t) |

Au (g/t) |

Cave Showing |

SCFS-24-010A |

681166 |

5212536 |

2.39 |

128 |

|

0.025 |

37 |

- |

|

SCFS-24-010B |

681166 |

5212536 |

3.61 |

7 |

|

0.025 |

28 |

- |

|

SCFS-24-010C |

681166 |

5212536 |

15.90 |

18 |

|

0.025 |

10 |

- |

|

SCFS-24-010D |

681166 |

5212536 |

4.08 |

7 |

|

0.025 |

23 |

- |

|

SCFS-24-010E |

681166 |

5212536 |

0.75 |

1 |

|

0.025 |

2.5 |

- |

Hydrothermal magnetite vein |

SCFS-24-020A |

681099 |

5212368 |

3.73 |

20 |

|

0.025 |

15 |

0.73 |

SCFS-24-020B |

681099 |

5212369 |

2.00 |

7 |

|

0.025 |

2.5 |

0.047 |

|

SCFS-24-020C |

681099 |

5212370 |

15.44 |

7 |

|

0.025 |

54 |

1.34 |

|

Moly Vein |

SCFS-24-016 |

681166 |

5212460 |

1.74 |

10000 |

4.84 |

3.04 |

7 |

- |

Regional Sampling |

SCFS-24-001 |

682771 |

5213881 |

0.013 |

1 |

|

0.025 |

2.5 |

- |

SCFS-24-002A |

682840 |

5214048 |

3.62 |

129 |

|

0.025 |

32 |

- |

|

SCFS-24-003 |

682841 |

5214071 |

0.028 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-004 |

680999 |

5212408 |

0.64 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-005 |

682030 |

5214507 |

0.043 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-006 |

681296 |

5214031 |

0.002 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-007 |

681296 |

5214031 |

0.002 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-008 |

681296 |

5214031 |

0.002 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-009 |

680361 |

5211774 |

0.061 |

7 |

|

0.025 |

2.5 |

- |

|

SCFS-24-011 |

681589 |

5212779 |

0.026 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-012 |

681178 |

5212518 |

0.20 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-013 |

681169 |

5212485 |

0.044 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-014 |

681168 |

5212486 |

0.99 |

38 |

|

0.025 |

9 |

- |

|

SCFS-24-015 |

681171 |

5212477 |

0.51 |

27 |

|

0.025 |

8 |

- |

|

SCFS-24-019 |

681103 |

5212371 |

0.48 |

46 |

|

0.025 |

2.5 |

- |

|

SCFS-24-021 |

681079 |

5212363 |

0.11 |

6 |

|

0.025 |

2.5 |

- |

|

SCFS-24-024 |

681111 |

5212510 |

1.54 |

4 |

|

0.025 |

37 |

- |

|

SCFS-24-027 |

680987 |

5212666 |

0.11 |

11 |

|

0.025 |

2.5 |

- |

|

SCFS-24-029 |

680931 |

5212700 |

1.69 |

7 |

|

0.025 |

2.5 |

- |

|

SCFS-24-037 |

678914 |

5214386 |

0.02 |

1 |

|

0.025 |

2.5 |

- |

|

SCFS-24-042 |

681777 |

5213319 |

0.83 |

5 |

|

0.025 |

2.5 |

- |

|

SCFS-24-049 |

681373 |

5213040 |

0.059 |

284 |

|

0.08 |

2.5 |

- |

Quality Assurance/Quality Control - Sampling Procedures

Soil samples were collected in areas containing available in situ material and areas such as wetlands were avoided. The soil samples consisted of 300-500 g of material collected from the B-horizon using a hand auger and stored in kraft bags. Samples were photographed, described, and final locations were recorded using a handheld GPS. The samples were air dried, sieved to an optimal fraction, split, packed into soil cups, covered with thin-film, and analyzed using a Vanta handheld XRF in a stationary setup. Internal quality control and quality assurance consisted of the insertion of certified reference materials and blank materials every 20-30 samples, and a duplicate analysis approximately every 50th sample. Procedural protocols were implemented at all stages of sample handling to prevent cross-contamination and external contamination of samples. A 10% subset of samples were selected from the survey and sent to SGS for analysis using a sodium peroxide fusion digest followed by ICP-OES/ICP-MS for lab verification.

Rock samples were bagged and labelled in the field, photographed, described, and assigned a coordinate using a handheld GPS. Samples were sent to SGS to be crushed, split and pulverized for analysis. Analysis included a sodium peroxide fusion digest followed by ICP-OES/ICP-MS. Ore grade and gold analysis were completed using fire assay, followed by an ICP-MS/ICP-AES finish. Certified reference materials and blank materials were inserted approximately every 20 samples by the laboratory.

Qualified Person

Jeremy Niemi, P.Geo., Senior Vice President, Exploration and Evaluation for Sterling Metals has reviewed and approved the technical information presented herein.

About Sterling Metals

Sterling Metals (TSXV:SAG) and (OTCQB:SAGGF) is a mineral exploration company focused on large scale and high-grade Canadian exploration opportunities. The Company is advancing the 25,000-hectare Copper Road Project in Ontario which has past production, and multiple breccia and porphyry targets strategically located near robust infrastructure and the 29,000-hectare Adeline Project in Labrador which covers an entire sediment-hosted copper belt with significant silver credits. Both opportunities have demonstrated potential for important new copper discoveries, underscoring Sterling's commitment to pioneering exploration in mineral rich Canada.

For more information, please contact:

Sterling Metals Corp.

Mathew Wilson, CEO and Director

Tel: (416) 643-3887

Email: info@sterlingmetals.ca

Website: www.sterlingmetals.ca

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release contains certain "forward-looking information" within the meaning of applicable securities laws. Forward-looking information is frequently characterized by words such as "plan", "expect", "project", "intend", "believe", "anticipate", "estimate", "may", "will", "would", "potential", "proposed" and other similar words, or statements that certain events or conditions "may" or "will" occur. These statements are only predictions. Forward-looking information is based on the opinions and estimates of management at the date the information is provided and is subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. For a description of the risks and uncertainties facing the Company and its business and affairs, readers should refer to the Company's Management's Discussion and Analysis. The Company undertakes no obligation to update forward-looking information if circumstances or management's estimates or opinions should change, unless required by law. The reader is cautioned not to place undue reliance on forward-looking information.

SOURCE: Sterling Metals Corp.

View the original press release on accesswire.com