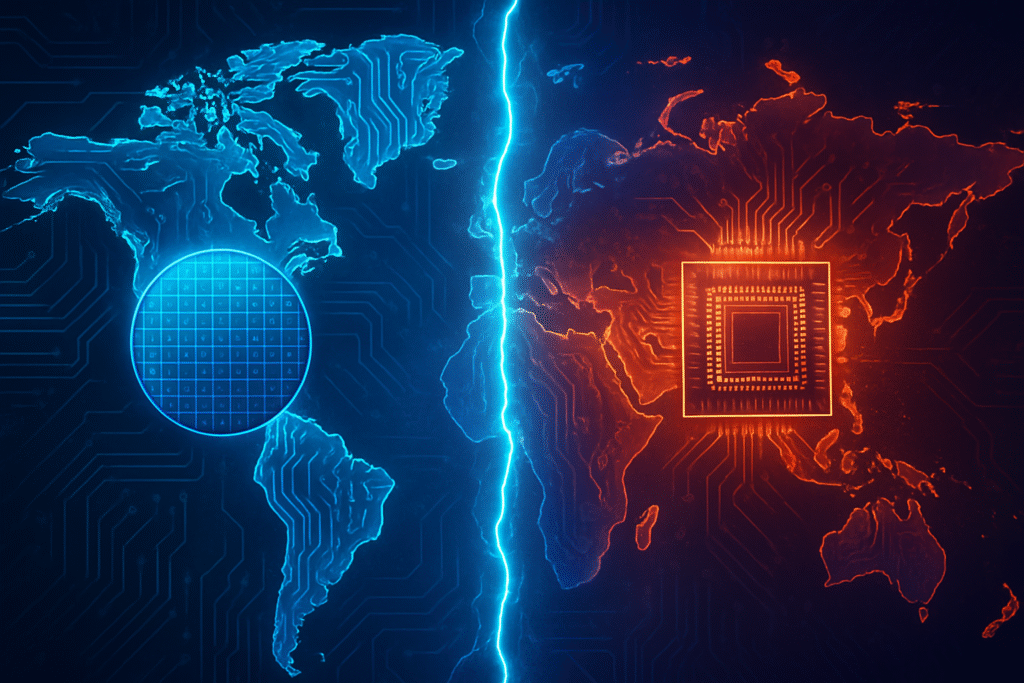

The global semiconductor industry, long characterized by its intricate, globally optimized supply chains, is undergoing a profound and rapid transformation. Driven by escalating geopolitical tensions and strategic trade policies, a "Silicon Curtain" is descending, fundamentally reshaping how critical microchips are designed, manufactured, and distributed. This shift moves away from efficiency-first models towards regionalized, resilience-focused ecosystems, with immediate and far-reaching implications for national security, economic stability, and the future of technological innovation. Nations are increasingly viewing semiconductors not just as commercial goods but as strategic assets, fueling an intense global race for technological supremacy and self-sufficiency, which in turn leads to fragmentation, increased costs, and potential disruptions across industries worldwide. This complex interplay of power politics and technological dependence is creating a new global order where access to advanced chips dictates economic prowess and strategic advantage.

A Web of Restrictions: Netherlands, China, and Australia at the Forefront of the Chip Conflict

The intricate dance of global power politics has found its most sensitive stage in the semiconductor supply chain, with the Netherlands, China, and Australia playing pivotal roles in the unfolding drama. At the heart of this technological tug-of-war is the Netherlands-based ASML (AMS: ASML), the undisputed monarch of lithography technology. ASML is the world's sole producer of Extreme Ultraviolet (EUV) lithography machines and a dominant force in Deep Ultraviolet (DUV) systems—technologies indispensable for fabricating the most advanced microchips. These machines are the linchpin for producing chips at 7nm process nodes and below, making ASML an unparalleled "chokepoint" in global semiconductor manufacturing.

Under significant pressure, primarily from the United States, the Dutch government has progressively tightened its export controls on ASML's technology destined for China. Initial restrictions blocked EUV exports to China in 2019. However, the measures escalated dramatically, with the Netherlands, in alignment with the U.S. and Japan, agreeing in January 2023 to impose controls on certain advanced DUV lithography tools. These restrictions came into full effect by January 2024, and by September 2024, even older models of DUV immersion lithography systems (like the 1970i and 1980i) required export licenses. Further exacerbating the situation, as of April 1, 2025, the Netherlands expanded its national export control measures to encompass more types of technology, including specific measuring and inspection equipment. Critically, the Dutch government, citing national and economic security concerns, invoked emergency powers in October 2025 to seize control of Nexperia, a Chinese-owned chip manufacturer headquartered in the Netherlands, to prevent the transfer of crucial technological knowledge. This unprecedented move underscores a new era where national security overrides traditional commercial interests.

China, in its determined pursuit of semiconductor self-sufficiency, views these restrictions as direct assaults on its technological ambitions. The "Made in China 2025" initiative, backed by billions in state funding, aims to bridge the technology gap, focusing heavily on expanding domestic capabilities, particularly in legacy nodes (28nm and above) crucial for a vast array of consumer and industrial products. In response to Western export controls, Beijing has strategically leveraged its dominance in critical raw materials. In July 2023, China imposed export controls on gallium and germanium, vital for semiconductor manufacturing. This was followed by a significant expansion in October 2025 of export controls on various rare earth elements and related technologies, introducing new licensing requirements for specific minerals and even foreign-made products containing Chinese-origin rare earths. These actions, widely seen as direct retaliation, highlight China's ability to exert counter-pressure on global supply chains. Following the Nexperia seizure, China further retaliated by blocking exports of components and finished products from Nexperia's China-based subsidiaries, escalating the trade tensions.

Australia, while not a chip manufacturer, plays an equally critical role as a global supplier of essential raw materials. Rich in rare earth elements, lithium, cobalt, nickel, silicon, gallium, and germanium, Australia's strategic importance lies in its potential to diversify critical mineral supply chains away from China's processing near-monopoly. Australia has actively forged strategic partnerships with the United States, Japan, South Korea, and the United Kingdom, aiming to reduce reliance on China, which processes over 80% of the world's rare earths. The country is fast-tracking plans to establish a A$1.2 billion (US$782 million) critical minerals reserve, focusing on future production agreements to secure long-term supply. Efforts are also underway to expand into downstream processing, with initiatives like Lynas Rare Earths' (ASX: LYC) facilities providing rare earth separation capabilities outside China. This concerted effort to secure and process critical minerals is a direct response to the geopolitical vulnerabilities exposed by China's raw material leverage, aiming to build resilient, allied-centric supply chains.

Corporate Crossroads: Navigating the Fragmented Chip Landscape

The seismic shifts in geopolitical relations are sending ripple effects through the corporate landscape of the semiconductor industry, creating a bifurcated environment where some companies stand to gain significant strategic advantages while others face unprecedented challenges and market disruptions. At the very apex of this complex dynamic is Taiwan Semiconductor Manufacturing Company (TSMC) (NYSE: TSM), the undisputed leader in advanced chip manufacturing. While TSMC benefits immensely from global demand for cutting-edge chips, particularly for Artificial Intelligence (AI), and government incentives like the U.S. CHIPS Act and European Chips Act, its primary vulnerability lies in the geopolitical tensions between mainland China and Taiwan. To mitigate this, TSMC is strategically diversifying its geographical footprint with new fabs in the U.S. (Arizona) and Europe, fortifying its role in a "Global Democratic Semiconductor Supply Chain" by increasingly excluding Chinese tools from its production processes.

Conversely, American giants like Intel (NASDAQ: INTC) are positioning themselves as central beneficiaries of the push for domestic manufacturing. Intel's ambitious IDM 2.0 strategy, backed by substantial federal grants from the U.S. CHIPS Act, involves investing over $100 billion in U.S. manufacturing and advanced packaging operations, aiming to significantly boost domestic production capacity. Samsung (KRX: 005930), a major player in memory and logic, also benefits from global demand and "friend-shoring" initiatives, expanding its foundry services and partnering with companies like NVIDIA (NASDAQ: NVDA) for custom AI chips. However, NVIDIA, a leading fabless designer of GPUs crucial for AI, has faced significant restrictions on its advanced chip sales to China due to U.S. trade policies, impacting its financial performance and forcing it to pivot towards alternative markets and increased R&D. ASML (AMS: ASML), despite its indispensable technology, is directly impacted by export controls, with expectations of a "significant decline" in its China sales for 2026 as restrictions limit Chinese chipmakers' access to its advanced DUV systems.

For Chinese foundries like Semiconductor Manufacturing International Corporation (SMIC) (HKG: 00981), the landscape is one of intense pressure and strategic resilience. Despite U.S. sanctions severely hampering their access to advanced manufacturing equipment and software, SMIC and other domestic players are making strides, backed by massive government subsidies and the "Made in China 2025" initiative. They are expanding production capacity for 7nm and even 5nm nodes to meet demand from domestic companies like Huawei, demonstrating a remarkable ability to innovate under duress, albeit remaining several years behind global leaders in cutting-edge technologies. The ban on U.S. persons working for Chinese advanced fabs has also led to a "mass withdrawal" of skilled personnel, creating significant talent gaps.

Tech giants such as Apple (NASDAQ: AAPL), Google (NASDAQ: GOOGL), Amazon (NASDAQ: AMZN), and Microsoft (NASDAQ: MSFT), as major consumers of advanced semiconductors, are primarily focused on enhancing supply chain resilience. They are increasingly pursuing vertical integration by designing their own custom AI silicon (ASICs) to gain greater control over performance, efficiency, and supply security, reducing reliance on external suppliers. While this ensures security of supply and mitigates future chip shortages, it can also lead to higher chip costs due to domestic production. Startups in the semiconductor space face increased vulnerability to supply shortages and rising costs due to their limited purchasing power, yet they also find opportunities in specialized niches and benefit from government R&D funding aimed at strengthening domestic semiconductor ecosystems. The overall competitive implication is a shift towards regionalization, intensified competition for technological leadership, and a fundamental re-prioritization of resilience and national security over pure economic efficiency.

The Dawn of Techno-Nationalism: Redrawing the Global Tech Map

The geopolitical fragmentation of semiconductor supply chains transcends mere trade disputes; it represents a fundamental redrawing of the global technological and economic map, ushering in an era of "techno-nationalism." This profound shift casts a long shadow over the broader AI landscape, where access to cutting-edge chips is no longer just a commercial advantage but a critical determinant of national security, economic power, and military capabilities. The traditional model of a globally optimized, efficiency-first semiconductor industry is rapidly giving way to fragmented, regional manufacturing ecosystems, effectively creating a "Silicon Curtain" that divides technological spheres. This bifurcation threatens to create disparate AI development environments, potentially leading to a technological divide where some nations have superior hardware, thereby impacting the pace and breadth of global AI innovation.

The implications for global trade are equally transformative. Governments are increasingly weaponizing export controls, tariffs, and trade restrictions as tools of economic warfare, directly targeting advanced semiconductors and related manufacturing equipment. The U.S. has notably tightened export controls on advanced chips and manufacturing tools to China, explicitly aiming to hinder its AI and supercomputing capabilities. These measures not only disrupt intricate global supply chains but also necessitate a costly re-evaluation of manufacturing footprints and supplier diversification, moving from a "just-in-time" to a "just-in-case" supply chain philosophy. This shift, while enhancing resilience, inevitably leads to increased production costs that are ultimately passed on to consumers, affecting the prices of a vast array of electronic goods worldwide.

The pursuit of technological independence has become a paramount strategic objective, particularly for major powers. Initiatives like the U.S. CHIPS and Science Act and the European Chips Act, backed by massive government investments, underscore a global race for self-sufficiency in semiconductor production. This "techno-nationalism" aims to reduce reliance on foreign suppliers, especially the highly concentrated production in East Asia, thereby securing control over key resources and technologies. However, this strategic realignment comes with significant concerns: the fragmentation of markets and supply chains can lead to higher costs, potentially slowing the pace of technological advancements. If companies are forced to develop different product versions for various markets due to export controls, R&D efforts could become diluted, impacting the beneficial feedback loops that optimized the industry for decades.

Comparing this era to previous tech milestones reveals a stark difference. Past breakthroughs in AI, like deep learning, were largely propelled by open research and global collaboration. Today, the environment threatens to nationalize and even privatize AI development, potentially hindering collective progress. Unlike previous supply chain disruptions, such as those caused by the COVID-19 pandemic, the current situation is characterized by the explicit "weaponization of technology" for national security and economic dominance. This transforms the semiconductor industry from an obscure technical field into a complex geopolitical battleground, where the geopolitical stakes are unprecedented and will shape the global power dynamics for decades to come.

The Shifting Sands of Tomorrow: Anticipating the Next Phase of Chip Geopolitics

Looking ahead, the geopolitical reshaping of semiconductor supply chains is far from over, with experts predicting a future defined by intensified fragmentation and strategic competition. In the near term (the next 1-5 years), we can expect a further tightening of export controls, particularly on advanced chip technologies, coupled with retaliatory measures from nations like China, potentially involving critical mineral exports. This will accelerate "techno-nationalism," with countries aggressively investing in domestic chip manufacturing through massive subsidies and incentives, leading to a surge in capital expenditures for new fabrication facilities in North America, Europe, and parts of Asia. Companies will double down on "friend-shoring" strategies to build more resilient, allied-centric supply chains, further reducing dependence on concentrated manufacturing hubs. This shift will inevitably lead to increased production costs and a deeply bifurcated global semiconductor market within three years, characterized by separate technological ecosystems and standards, along with an intensified "talent war" for skilled engineers.

Longer term (beyond 5 years), the industry is likely to settle into distinct regional ecosystems, each with its own supply chain, potentially leading to diverging technological standards and product offerings across the globe. While this promises a more diversified and potentially more secure global semiconductor industry, it will almost certainly be less efficient and more expensive, marking a permanent shift from "just-in-time" to "just-in-case" strategies. The U.S.-China rivalry will remain the dominant force, sustaining market fragmentation and compelling companies to develop agile strategies to navigate evolving trade tensions. This ongoing competition will not only shape the future of technology but also fundamentally alter global power dynamics, where technological sovereignty is increasingly synonymous with national security.

Challenges on the horizon include persistent supply chain vulnerabilities, especially concerning Taiwan's critical role, and the inherent inefficiencies and higher costs associated with fragmented production. The acute shortage of skilled talent in semiconductor engineering, design, and manufacturing will intensify, further complicated by geopolitically influenced immigration policies. Experts predict a trillion-dollar semiconductor industry by 2030, with the AI chip market alone exceeding $150 billion in 2025, suggesting that while the geopolitical landscape is turbulent, the underlying demand for advanced chips, particularly for AI, electric vehicles, and defense systems, will only grow. New technologies like advanced packaging and chiplet-based architectures are expected to gain prominence, potentially offering avenues to reduce reliance on traditional silicon manufacturing complexities and further diversify supply chains, though the overarching influence of geopolitical alignment will remain paramount.

The Unfolding Narrative: A New Era for Semiconductors

The global semiconductor industry stands at an undeniable inflection point, irrevocably altered by the complex interplay of geopolitical tensions and strategic trade policies. The once-globally optimized supply chain is fragmenting into regionalized ecosystems, driven by a pervasive "techno-nationalism" where semiconductors are viewed as critical strategic assets rather than mere commercial goods. The actions of nations like the Netherlands, with its critical ASML (AMS: ASML) technology, China's aggressive pursuit of self-sufficiency and raw material leverage, and Australia's pivotal role in critical mineral supply, exemplify this fundamental shift. Companies from TSMC (NYSE: TSM) to Intel (NASDAQ: INTC) are navigating this fragmented landscape, diversifying investments, and recalibrating strategies to prioritize resilience over efficiency.

This ongoing transformation represents one of the most significant milestones in AI and technological history, marking a departure from an era of open global collaboration towards one of strategic competition and technological decoupling. The implications are vast, ranging from higher production costs and potential slowdowns in innovation to the creation of distinct technological spheres. The "Silicon Curtain" is not merely a metaphor but a tangible reality that will redefine global trade, national security, and the pace of technological progress for decades to come.

As we move forward, the U.S.-China rivalry will continue to be the primary catalyst, driving further fragmentation and compelling nations to align or build independent capabilities. Watch for continued government interventions in the private sector, intensified "talent wars" for semiconductor expertise, and the emergence of innovative solutions like advanced packaging to mitigate supply chain vulnerabilities. The coming weeks and months will undoubtedly bring further strategic maneuvers, retaliatory actions, and unprecedented collaborations as the world grapples with the profound implications of this new era in semiconductor geopolitics. The future of technology, and indeed global power, will be forged in the foundries and mineral mines of this evolving landscape.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.